ICH Q7 Compliance for APIs

Manufactured by Cell Culture/Fermentation

Monday - Joint Programme

COMPLIANCE SESSION PART 1 – MANAGEMENT PROCESS

APIC’s "How to do" Guide and further APIC Activities

- Information on APIC

- Contribution to GMP Compliance and Supply Chain Integrity

- How to do Document

- Quality Agreements

- ASMF Guideline

- FMD and GDP for APIs - ICH Q7 Q&A How to do Document

- Further activities

ICH – A General Introduction

- What is ICH?

- API related ICH Guidelines

- ICH Quality Guidelines

- ICH Q7 – Hot topics and requirements

- Overview of guidance documents (Q8 to Q14)

Regulatory Framework - an Inspector’s View

- Overview: relevant guidelines

- Inspections in drug product facilities - relevant topics for API manufacturers

- Recent findings in inspections

ICH Q7 Q&A – What to do and how to do

- Overview about the ICH Q7 Questions and Answers Document

- Some Highlights from the Q&A Document and their interpretation

- Distribution procedures, intercontinental shipments

- Risk assessment and validation

- Complaints and recalls

Preparing for GMP Inspections

- Experience with GMP inspections of API manufacturers

- Major findings/observations during inspections

- Dos and Don’ts during inspections

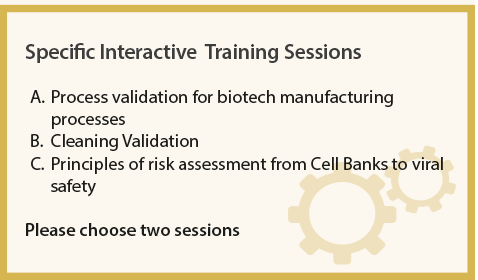

Tuesday - Parallel Sessions

COMPLIANCE SESSION PART 2 – Product and QC Issues

GMP Inspections at Biotech Companies

- Special considerations for inspections at Biotech Companies

- Cell Banks Facility

- Biological Materials and Culture Media

- Fermentation

- Viral removal/inactivation

- Laboratories

- Recent regulatory findings

- Most common FDA audit observations

Instances of Virus Contamination in GMP manufactured Products

– what can we learn?

- Virus contamination in GMP manufactured products (examples)

- How to implement continued vigilance with regard to potential virus contamination

- Virus contamination and root cause analysis

- Application of appropriate risk control measures

- Approaches to minimise the risk of contamination

Cleaning and Cleaning Validation in Biotech Manufacturing Processes

- Identification of cleaning mechanisms and selection of cleaning agents

- Selection of analytical methods for the detection of residues

- Establishment of limits in fermentation and downstream processing

- Grouping strategies

- Final rinse versus swab testing

Cellbanking –Master Cell Banks (MCB) and Working Cell Banks (WCB)

- Establishment of MCB and WCB

- Definition of ’API starting material’

- Cell Bank qualification and testing

- Cell Bank maintenance and record keeping

Wednesday Morning - Joint Programme

COMPLIANCE SESSION PART 3 –Life Cycle Management and Continuous Improvement

Supply Chain Life Cycle: Reduced Testing and Supplier Qualification

- ICH Q7 requirements

- Supplier qualification covering the full supply chain

- One strategy for supplier qualification from non-critical raw material to API

- Requirements and strategy for reduced testing (CoA release) of materials

Internal Change Control Management

- Drivers for Change

- The regulations´ view on changes

- The Importance of Change Control

- Elements of a Change Control System

- Roles & Responsibilities

- Detailed Requirements for Specific Changes

- Implementation of Changes

How to implement ICH Q3D

- Regulatory requirements

- „Five steps implementation strategy“

- How to handle CEP updates and new registrations from the perspective of the Marketing Authorisation Holder

Data Integrity in the Light of ICH Q7

- Which requirements are applicable to APIs under ICH Q7?

- Specific Requirements and Interpretations

- Consideration for specific risks

- The hubris of hybrid records

- Case study: how to achieve Data Integrity on a risk-based approach

Stability Testing of APIs

- Stability Specification

- Stability Studies

- Stability test methods

- Stress tests

- Packaging

- Guidance on API stability testing